Manufacturing Technology 2 provides modern industries with solutions to the challenges that arise from traditional manufacturing methods, such as lack of time efficiency, accuracy, and overall productivity. Today, companies face increasing pressure to produce high-precision parts, achieve faster production cycles, and minimize material waste needs that older techniques cannot fulfill.

Manufacturing Technology 2 effectively addresses these problems by introducing advanced machines, automation tools, improved material-handling systems, and smart production processes. These modern methods not only enhance output but also reduce costs and significantly improve the overall quality of manufactured products.

What Manufacturing Technology 2 Covers In Simple Terms

Manufacturing Technology 2 is an intermediate-level course that explores how products are made in factories and workshops. Think of it as the bridge between basic manufacturing concepts and real-world industrial production.

At its core, Manufacturing Technology 2 teaches you three essential things. First, you learn about different processes for shaping materials. This includes cutting metals on lathes, pouring molten metal into molds, and welding pieces together. Second, you understand the machines and tools that make these processes possible. Third, you discover how modern technology like CNC machines and robots are changing manufacturing.

Why does this matter? Every physical product you use went through manufacturing processes. Your coffee mug was shaped on a potter’s wheel or molded in a factory. Your bicycle frame was welded from metal tubes. Your laptop case was injection molded from plastic. Understanding these processes helps you appreciate how products come to life and opens doors to rewarding careers.

Manufacturing Technology 2 connects directly to real products in important ways. When you learn about machining, you understand how engine parts achieve their precise dimensions. When you study casting, you see how complex shapes like engine blocks are formed. When you explore CNC programming, you grasp how manufacturers produce thousands of identical parts efficiently.

The knowledge from Manufacturing Technology 2 applies across industries. Automotive companies use these processes to build cars. Aerospace firms apply them to create aircraft components. Medical device manufacturers rely on them for surgical instruments. Even consumer electronics depend on manufacturing technologies for cases, connectors, and internal parts.

Who This Manufacturing Technology 2 Guide Is For

This guide serves several groups of readers who want to understand manufacturing processes better.

Engineering Students

If you’re studying mechanical engineering, industrial engineering, or manufacturing engineering, this guide reinforces your classroom learning. Manufacturing Technology 2 is a core course in most engineering programs. The explanations here complement your textbooks and lecture notes with practical examples.

Students in the USA will find this guide aligned with typical university curricula. The same applies to students in the UK, where manufacturing technology appears in engineering degree programs. Australian and Canadian students following similar course structures will benefit equally. German students studying Fertigungstechnik will recognize many concepts translated into English here.

Technical College Students

Community college students in the USA and TAFE students in Australia often take manufacturing technology courses as part of technician training programs. This guide helps you understand concepts without assuming advanced mathematics or prior engineering knowledge.

Career Changers

Perhaps you’re working in another field but considering manufacturing as a new career path. Manufacturing offers stable employment, competitive wages, and opportunities for advancement. This guide gives you a foundation to decide if this path suits you and prepares you for entry-level training.

Curious Learners

Maybe you simply want to understand how things are made. There’s something satisfying about knowing how a raw piece of metal becomes a precision part. This guide satisfies that curiosity while teaching practical knowledge.

Regardless of which group you belong to, this guide assumes you have basic knowledge of high school level science and mathematics. You don’t need prior manufacturing experience, though familiarity with tools and workshops helps.

What Is Manufacturing Technology 2

Understanding what Manufacturing Technology 2 covers helps you approach the subject with the right expectations. This section defines the course, describes typical content, and explains how it builds on earlier learning.

Definition And Main Goals Of Manufacturing Technology 2

Manufacturing Technology 2 is an educational course that teaches intermediate and advanced concepts in industrial production processes. It covers the methods, machines, and principles used to transform raw materials into finished products at industrial scale.

The formal definition varies slightly between institutions, but the essence remains consistent. Manufacturing Technology 2 examines material removal processes, forming processes, joining processes, and modern computer-controlled manufacturing methods.

The main learning goals of Manufacturing Technology 2 typically include:

Understanding Process Selection

Students learn to choose appropriate manufacturing processes for different parts. A simple shaft might be turned on a lathe, while a complex housing might require casting followed by machining. Manufacturing Technology 2 teaches the reasoning behind these choices.

Mastering Process Parameters

Each manufacturing process has variables that affect the outcome. Cutting speed, feed rate, and depth of cut matter in machining. Temperature, pressure, and cooling rate matter in casting. Manufacturing Technology 2 teaches how to set these parameters correctly.

Operating Workshop Equipment

Hands-on laboratory work forms a crucial part of Manufacturing Technology 2. Students learn to operate lathes, milling machines, drilling machines, and often CNC equipment. This practical experience builds confidence and skills.

Applying Quality Principles

Manufacturing Technology 2 teaches measurement and inspection. Students learn to use precision instruments, understand tolerances, and verify that parts meet specifications.

Connecting Theory To Practice

Perhaps most importantly, Manufacturing Technology 2 bridges academic theory and industrial reality. Students see how equations from physics and materials science apply to real manufacturing situations.

By completing Manufacturing Technology 2, students gain competence in fundamental manufacturing processes and readiness for advanced topics or industrial employment.

Typical Manufacturing Technology 2 Syllabus In The USA And Beyond

While specific content varies between institutions, most Manufacturing Technology 2 courses share common elements. Here’s what you can typically expect to find in a Manufacturing Technology 2 syllabus.

Module 1: Review of Fundamentals

Most courses begin with a quick review of concepts from Manufacturing Technology 1 or equivalent courses. This includes material properties, basic process classifications, and workshop safety. The review ensures all students share a common foundation before advancing.

Module 2: Metal Cutting Theory

This module covers the physics of chip formation, cutting forces, heat generation, and tool wear. Students learn why certain cutting conditions work better than others. Mathematical relationships between cutting speed, feed, and depth of cut are introduced.

Module 3: Machining Processes

The heart of Manufacturing Technology 2 often lies in detailed coverage of machining. This includes:

- Turning operations on lathes

- Milling operations on horizontal and vertical mills

- Drilling, boring, and reaming

- Grinding and finishing operations

- Gear cutting and specialized processes

Each process receives attention regarding setup, tooling, parameters, and typical applications.

Module 4: Casting Processes

Students explore sand casting, investment casting, die casting, and other methods for creating parts from molten material. Pattern making, mold design, and defect prevention receive coverage.

Module 5: Metal Forming

Forging, rolling, extrusion, drawing, and sheet metal operations fill this module. Students learn how plastic deformation shapes metals without material removal.

Module 6: Joining Processes

Welding dominates this section, covering arc welding, gas welding, resistance welding, and modern methods like laser welding. Brazing, soldering, and mechanical fastening also appear.

Module 7: CNC and Automation

Modern Manufacturing Technology 2 courses include computer numerical control fundamentals. Students learn G-code basics, understand how CNC machines work, and often program simple parts.

Module 8: Metrology and Quality

Measurement instruments, geometric tolerances, and inspection methods conclude many courses. Students learn to verify that manufactured parts meet design specifications.

Laboratory Work

Alongside lectures, Manufacturing Technology 2 includes substantial laboratory time. Students operate machines, measure parts, and complete projects. Many courses require students to manufacture a complete part from start to finish.

In the USA, this content typically fills a three or four credit hour course over one semester. UK programs may structure it differently within modular degree systems. Australian and Canadian universities follow similar patterns, while German programs often integrate practical training more intensively.

How Manufacturing Technology 2 Builds On Earlier Courses

Manufacturing Technology 2 assumes prior knowledge from introductory courses. Understanding this progression helps you see where Manufacturing Technology 2 fits in your learning journey.

What Manufacturing Technology 1 Covers

The first course in manufacturing technology typically introduces:

- Classification of manufacturing processes

- Properties of engineering materials

- Basic concepts of each major process category

- Introduction to workshop tools and safety

- Simple hands-on projects

Manufacturing Technology 1 provides breadth. It exposes students to many processes without deep detail. You learn that lathes exist and what they do, but you might not calculate cutting forces or optimize parameters.

How Manufacturing Technology 2 Goes Deeper

Manufacturing Technology 2 adds depth to the breadth from the first course. Where Manufacturing Technology 1 introduces turning, Manufacturing Technology 2 teaches you to calculate spindle speed based on cutting velocity and workpiece diameter. Where the first course mentions tool wear, the second course explains Taylor’s tool life equation.

The progression looks like this:

| Topic | Manufacturing Technology 1 | Manufacturing Technology 2 |

| Turning | What a lathe does | Calculating speeds, feeds, forces, and tool life |

| Casting | Basic sand casting concept | Pattern design, gating, risering, and defect prevention |

| Welding | Types of welds and joints | Heat affected zones, distortion, and weld design |

| Quality | Why measurement matters | Using instruments, understanding tolerances |

| CNC | Awareness that CNC exists | Programming basics and machine operation |

Prerequisites You Need

Before taking Manufacturing Technology 2, you should have:

- Completed Manufacturing Technology 1 or equivalent

- Basic understanding of material properties

- Ability to read engineering drawings

- Comfort with algebra and basic physics

- Workshop safety awareness

If you’re missing some prerequisites, review relevant material before starting Manufacturing Technology 2. Many students struggle not because the content is inherently difficult, but because gaps in foundational knowledge create confusion.

What Comes After Manufacturing Technology 2

Manufacturing Technology 2 prepares you for several paths:

- Advanced manufacturing courses focusing on specific areas

- Computer integrated manufacturing studies

- Industrial engineering and production planning courses

- Direct entry into manufacturing roles

The skills from Manufacturing Technology 2 remain relevant throughout your career, whether you continue formal education or enter industry directly.

Core Manufacturing Processes In Manufacturing Technology 2

The heart of Manufacturing Technology 2 lies in understanding core manufacturing processes. This section covers the major process categories in detail, explaining how each works and where it applies.

Machining Turning, Milling, And Drilling

Machining removes material from a workpiece to achieve desired shape and size. It’s one of the most versatile and widely used manufacturing process families. Manufacturing Technology 2 covers machining extensively because of its industrial importance.

Understanding Material Removal

All machining processes share a common principle. A cutting tool harder than the workpiece moves against the material, shearing away small pieces called chips. The tool’s geometry, the relative motion between tool and work, and the process parameters determine the outcome.

Turning Operations

Turning uses a lathe to create cylindrical parts. The workpiece rotates while a stationary cutting tool removes material.

Basic turning operations include:

- Facing: Creating a flat surface on the end of a cylinder

- Straight turning: Reducing diameter along the length

- Taper turning: Creating conical shapes

- Threading: Cutting screw threads

- Boring: Enlarging internal holes

- Parting: Cutting off completed parts

Here’s how to set up a basic turning operation:

- Mount the workpiece securely in the chuck

- Select appropriate cutting tool for the operation

- Set spindle speed based on cutting velocity and diameter

- Set feed rate based on surface finish requirements

- Set depth of cut considering tool and machine capacity

- Engage feed and monitor the operation

- Measure result and adjust if needed

The cutting speed formula helps you calculate spindle speed:

N = (V × 1000) / (π × D)

Where N is spindle speed in RPM, V is cutting velocity in meters per minute, and D is workpiece diameter in millimeters.

Milling Operations

Milling uses rotating multi-point cutters to remove material. Unlike turning, the tool rotates while the workpiece typically moves linearly.

Manufacturing Technology 2 covers several milling types:

- Plain milling: Creating flat surfaces

- Face milling: Machining surfaces perpendicular to the spindle

- End milling: Creating slots, pockets, and contours

- Slot milling: Cutting narrow channels

- Form milling: Creating shaped profiles

Milling machines come in two main configurations. Horizontal mills have spindles parallel to the table, suited for plain milling and slotting. Vertical mills have spindles perpendicular to the table, ideal for face milling and end milling.

Key milling parameters include:

- Spindle speed (RPM)

- Feed rate (mm per minute or per tooth)

- Depth of cut

- Width of cut

Drilling Operations

Drilling creates holes in workpieces using rotating drill bits. While conceptually simple, proper drilling technique prevents problems like wandering holes, poor surface finish, and broken drills.

Drilling operations covered in Manufacturing Technology 2 include:

- Center drilling: Creating starting points for larger drills

- Through drilling: Holes that penetrate completely

- Blind drilling: Holes that stop at specified depth

- Step drilling: Creating holes with multiple diameters

- Reaming: Finishing drilled holes for accuracy

- Counterboring and countersinking: Creating recesses for fastener heads

Drilling speed calculations follow similar principles to turning, but the effective diameter is the drill size. Feed rates for drilling are typically expressed as distance per revolution rather than distance per minute.

Example: Making a Simple Shaft

Consider a simple stepped shaft with two diameters. Manufacturing Technology 2 teaches the complete process:

- Start with round bar stock slightly larger than the biggest diameter

- Face both ends to establish length reference

- Turn the larger diameter to specification

- Turn the smaller diameter portion

- If needed, add features like keyways or threads

- Perform finishing cuts for required surface quality

- Measure final dimensions

This example shows how turning operations combine to create complete parts.

Casting, Forming, And Shaping Of Metals And Plastics

Not all manufacturing involves cutting away material. Casting creates shapes by pouring liquid material into molds. Forming reshapes solid material through plastic deformation. Manufacturing Technology 2 covers both families comprehensively.

Casting Fundamentals

Casting produces parts by pouring molten metal or other material into shaped molds. Once solidified, the mold is removed to reveal the part.

Manufacturing Technology 2 covers several casting methods:

Sand Casting

The most versatile and common casting process uses sand molds. A pattern shaped like the desired part creates a cavity in packed sand. Molten metal fills this cavity and solidifies.

The sand casting process involves:

- Creating a pattern (usually wood or plastic)

- Making the mold by packing sand around the pattern

- Removing the pattern, leaving a cavity

- Adding gating system for metal flow

- Adding risers for shrinkage compensation

- Pouring molten metal

- Allowing solidification

- Breaking away the mold

- Cleaning and finishing the casting

Sand casting works for almost any metal and can produce parts from a few ounces to several tons. It’s economical for small quantities since molds are expendable.

Investment Casting

Also called lost wax casting, this process creates very precise parts. A wax pattern is coated with ceramic slurry, then the wax is melted out, leaving a ceramic mold. Investment casting produces complex shapes with excellent surface finish.

Die Casting

For high production volumes, die casting forces molten metal into permanent steel molds under pressure. The process is fast and produces consistent results, making it ideal for parts like automotive components and appliance housings.

Common Casting Defects

Manufacturing Technology 2 teaches students to recognize and prevent casting defects:

- Porosity: Gas bubbles trapped in solidifying metal

- Shrinkage cavities: Voids caused by volume reduction during solidification

- Hot tears: Cracks from thermal stresses

- Misruns: Incomplete filling of the mold

- Cold shuts: Where two metal streams meet without fusing

Proper mold design, gating system design, and process control prevent most defects.

Metal Forming Processes

Forming reshapes material through plastic deformation without melting. The material changes shape but material is neither added nor removed.

Forging

Forging uses compressive force to shape metal. Hot forging heats metal until it’s easily deformed. Cold forging works at room temperature for certain metals and produces stronger parts.

Forging methods include:

- Open die forging: Metal is shaped between flat dies

- Closed die forging: Metal fills shaped die cavities

- Roll forging: Reduces cross-section while increasing length

- Press forging: Uses slow squeezing rather than impact

Forged parts have excellent strength because the metal’s grain structure follows the part shape.

Rolling

Rolling passes metal between rotating rolls to reduce thickness or change cross-section. Hot rolling produces structural shapes, plates, and sheets. Cold rolling creates thinner sheets with better surface finish.

Extrusion

Extrusion forces metal through a shaped die opening, like squeezing toothpaste from a tube. The process creates continuous lengths of uniform cross-section. Aluminum window frames and electrical conduit are typically extruded.

Sheet Metal Forming

Many products use formed sheet metal:

- Bending creates angular shapes

- Deep drawing produces cup-shaped parts

- Stamping combines cutting and forming

- Spinning creates symmetrical hollow shapes

Automobile body panels, appliance housings, and beverage cans all involve sheet metal forming.

Plastic Processing

Manufacturing Technology 2 often includes plastic manufacturing:

- Injection molding: Forces molten plastic into molds

- Extrusion: Creates continuous plastic profiles

- Blow molding: Makes hollow plastic containers

- Thermoforming: Shapes heated plastic sheets

These processes share principles with metal forming but account for different material behavior.

Welding, Joining, And Surface Finishing Basics

Joining processes combine separate pieces into assemblies. Surface finishing improves appearance, wear resistance, or corrosion protection. Manufacturing Technology 2 covers both areas.

Welding Fundamentals

Welding creates permanent joints by melting base metals together, often with added filler metal. The resulting joint can be as strong as the base material.

Arc Welding Processes

Electric arc welding uses an electrical discharge to generate heat:

Shielded Metal Arc Welding (SMAW)

Also called stick welding, SMAW uses consumable electrodes coated with flux. The flux creates protective gas and slag. It’s versatile and works outdoors, making it common for construction and repair.

Gas Metal Arc Welding (GMAW)

Called MIG welding, this process feeds wire electrodes continuously while shielding gas protects the weld. It’s faster than SMAW and easier to learn, making it popular in manufacturing.

Gas Tungsten Arc Welding (GTAW)

Called TIG welding, this uses a non-consumable tungsten electrode with a separate filler rod. It produces high-quality welds on thin materials and is common for aerospace and food equipment.

Other Welding Processes

- Resistance welding: Uses electrical resistance to generate heat, common for sheet metal assembly

- Gas welding: Uses burning gas for heat, now mainly for repair and artistic work

- Laser welding: Uses focused light for precision joining

- Electron beam welding: Uses electron beam in vacuum for critical applications

Weld Quality Factors

Manufacturing Technology 2 teaches weld quality considerations:

- Proper joint preparation

- Correct electrode or filler selection

- Appropriate welding parameters

- Control of distortion

- Inspection and testing

Non-Welding Joining Methods

Not all joining requires melting:

Brazing and Soldering

Both use filler metals that melt below the base metal temperature. Brazing uses higher temperatures (above 450°C) and produces stronger joints. Soldering uses lower temperatures and is common for electronics.

Mechanical Fastening

Bolts, screws, rivets, and other fasteners create joints that can often be disassembled. Proper fastener selection considers loads, materials, and service conditions.

Adhesive Bonding

Modern adhesives create strong joints between various materials. They’re important for composite materials and mixed-material assemblies.

Surface Finishing

Surface finishing improves parts in several ways:

Mechanical Finishing

- Grinding produces accurate dimensions and smooth surfaces

- Polishing creates mirror-like surfaces

- Shot peening improves fatigue strength

- Buffing enhances appearance

Coating Processes

- Painting provides color and corrosion protection

- Plating adds metal layers for wear or corrosion resistance

- Anodizing creates protective oxide layers on aluminum

- Powder coating applies durable polymer finishes

Heat Treatment

While technically a material process, heat treatment often occurs during manufacturing:

- Hardening increases surface or through hardness

- Tempering balances hardness and toughness

- Annealing softens material for processing

- Case hardening creates hard surfaces on tough cores

Manufacturing Technology 2 introduces these concepts so students understand complete manufacturing sequences.

Machines And Tools Used In Manufacturing Technology 2

Knowing processes means little without understanding the machines and tools that perform them. Manufacturing Technology 2 includes substantial content on workshop equipment.

Conventional Machine Tools Lathes, Mills, And Drills

Conventional machine tools use manual controls and operator skill. While CNC machines dominate modern production, conventional machines remain important for toolroom work, prototyping, and understanding fundamentals.

The Engine Lathe

The lathe is perhaps the most fundamental machine tool. It rotates workpieces while tools remove material, creating cylindrical shapes.

Key lathe components include:

- Headstock: Contains the spindle that rotates the workpiece

- Tailstock: Supports long workpieces and holds drilling tools

- Carriage: Carries the cutting tool and provides feeding motion

- Bed: The base that maintains alignment between components

- Lead screw: Enables thread cutting operations

- Chuck: Grips the workpiece for rotation

Operating a lathe requires understanding:

- How to mount workpieces securely

- How to select and set cutting tools

- How to use handwheels for positioning

- How to engage power feed

- How to read the dials for dimensions

Manufacturing Technology 2 laboratory work typically includes lathe projects that develop these skills.

Milling Machines

Milling machines move workpieces against rotating cutters to create various features.

Vertical Milling Machines

The vertical mill has its spindle perpendicular to the table. It excels at:

- Face milling flat surfaces

- End milling slots and pockets

- Drilling and boring operations

- Creating complex contours

The knee-and-column vertical mill is the most common type in educational workshops. Its table can move in three directions (X, Y, and Z), allowing precise positioning.

Horizontal Milling Machines

Horizontal mills have spindles parallel to the table. They work well for:

- Plain milling wide surfaces

- Gang milling with multiple cutters

- Cutting gears and splines

Key milling machine components include:

- Spindle for rotating cutters

- Table for mounting workpieces

- Saddle for cross-movement

- Knee for vertical adjustment

- Overarm (horizontal mills) for arbor support

Drilling Machines

Drilling machines range from simple bench drills to large radial arm drills:

Bench Drill Press

Small, tabletop machines for light drilling. They handle small drill sizes in thin workpieces.

Floor Drill Press

Larger, more powerful machines for heavier work. They include features like power feed and better spindle bearings.

Radial Drill Press

For large workpieces, the radial drill allows positioning the spindle rather than moving the work. The arm swings and the head moves along it, reaching different locations on large parts.

All drilling machines share common elements:

- Spindle that rotates the drill

- Quill that feeds the spindle vertically

- Table or base for workpiece support

- Column for structural support

- Speed change mechanism

Other Conventional Machines

Manufacturing Technology 2 may also cover:

- Surface grinders for precision flat surfaces

- Shapers and planers for flat surface generation

- Broaching machines for internal shapes

- Sawing machines for cutting stock

Cutting Tools, Tool Materials, And Tool Wear

Cutting tools directly contact workpieces and remove material. Their design and material significantly affect manufacturing outcomes.

Tool Geometry

Cutting tools have specific geometric features:

- Rake angle: Affects chip flow and cutting forces

- Relief angle: Prevents rubbing behind the cutting edge

- Cutting edge angle: Influences chip width and thickness

- Nose radius: Affects surface finish and tool strength

Positive rake angles reduce cutting forces but weaken the edge. Negative rake angles strengthen the edge for hard materials. Manufacturing Technology 2 teaches how to select appropriate geometry for different materials and operations.

Tool Materials

The material a tool is made from determines its capabilities:

High-Speed Steel (HSS)

HSS tools maintain hardness at elevated temperatures caused by cutting heat. They’re:

- Relatively inexpensive

- Easy to resharpen

- Tough and resistant to breakage

- Suitable for moderate cutting speeds

HSS remains common for drills, taps, and tools for manual machines.

Cemented Carbide

Carbide tools consist of tungsten carbide particles in cobalt binder. They offer:

- Much higher hardness than HSS

- Excellent wear resistance

- Capability for high cutting speeds

- Available as inserts for easy replacement

Carbide dominates modern production machining. Indexable carbide inserts clamp to holders and are replaced when worn rather than resharpened.

Ceramics

Ceramic tools provide even higher hardness and heat resistance. They work at very high speeds on cast iron and hardened steel but are brittle and sensitive to shock.

Cubic Boron Nitride (CBN)

Second only to diamond in hardness, CBN tools machine hardened steels and superalloys. They’re expensive but enable finishing operations that otherwise require grinding.

Diamond

Natural and synthetic diamond tools machine non-ferrous materials like aluminum and copper alloys. Diamond reacts with iron at high temperatures, so it’s not used for steel.

Coatings

Modern tools often have thin coatings that improve performance:

- TiN (titanium nitride) reduces friction and wear

- TiCN offers higher hardness

- TiAlN provides better heat resistance

- Diamond-like carbon (DLC) works for non-ferrous materials

Tool Wear

All cutting tools wear during use. Manufacturing Technology 2 teaches recognition and management of tool wear.

Types of Wear

- Flank wear: Wear on the relief face from friction

- Crater wear: Wear on the rake face from chip flow

- Notch wear: Localized wear at the depth of cut line

- Chipping: Small pieces breaking from the edge

Taylor’s Tool Life Equation

The relationship between cutting speed and tool life is expressed:

VT^n = C

Where V is cutting speed, T is tool life, and n and C are constants for the material and tool combination. This equation helps optimize cutting conditions.

Managing Tool Wear

Strategies for managing tool wear include:

- Monitoring wear and replacing tools before failure

- Using appropriate cutting fluids

- Selecting correct cutting parameters

- Choosing suitable tool materials

Workshop Safety Rules For Manufacturing Technology 2 Labs

Workshop safety isn’t just a list of rules, it’s a mindset that protects you and others. Manufacturing Technology 2 laboratories involve hazards that require constant awareness.

Personal Protective Equipment

Always wear appropriate PPE:

- Safety glasses: Protect eyes from chips and coolant

- Safety shoes: Protect feet from falling objects

- Ear protection: Guard against machine noise

- Appropriate clothing: No loose sleeves, ties, or jewelry

Never wear gloves near rotating machinery. They can catch and pull your hand into the machine.

Machine-Specific Lathe Safety

- Never adjust chuck while spindle rotates

- Use chuck key and remove it immediately after use

- Keep hands clear of rotating workpiece

- Stop machine before measuring

- Secure long workpieces with tailstock or steady rest

- Use chip guards and never touch rotating chips

Milling Machine Safety

- Secure workpiece firmly before cutting

- Keep fingers away from rotating cutters

- Use appropriate fixtures and clamps

- Stop machine before adjusting

- Clean chips with brush, not hands

Drilling Machine Safety

- Clamp workpiece; never hold by hand

- Center punch before drilling to prevent wandering

- Reduce feed rate when drill breaks through

- Never wear gloves when drilling

General Workshop Rules

- Know emergency stop locations for all machines

- Never operate machines without training

- Ask questions when uncertain

- Report malfunctions immediately

- Keep work area clean

- No horseplay in the workshop

- Never work alone in the shop

Housekeeping

Good housekeeping prevents accidents:

- Clean up chips and spills promptly

- Return tools to proper locations

- Keep floors clear of obstructions

- Dispose of oily rags in metal containers

- Maintain clear access to emergency equipment

Emergency Procedures

Know what to do when things go wrong:

- Location of first aid kit

- How to respond to injuries

- Fire extinguisher locations and use

- Emergency contact numbers

Safety in Manufacturing Technology 2 labs teaches habits that protect you throughout your career. Treat every operation with respect, and never compromise safety for speed.

CNC, CAD CAM, And Automation In Manufacturing Technology 2

Modern manufacturing relies heavily on computers and automation. Manufacturing Technology 2 introduces these technologies that have transformed production.

How CNC Machines Work In Manufacturing Technology 2

Computer Numerical Control (CNC) uses computers to control machine tools. Understanding CNC is essential for modern manufacturing careers.

The Concept of Numerical Control

Before CNC, machinists manually controlled every machine movement. Numerical control (NC) replaced manual control with programmed instructions. The computer in CNC added processing power and memory to NC.

A CNC machine follows programmed commands that specify:

- Where to move

- How fast to move

- When to start and stop cutting

- Which tool to use

- Spindle speed and coolant activation

CNC Machine Components

CNC machines include:

Machine Control Unit (MCU)

The computer that reads programs, processes commands, and controls the machine. Modern MCUs have touchscreen interfaces, onboard program editing, and network connectivity.

Servo Systems

Motors and encoders that precisely control axis movement. The control system continuously compares commanded position with actual position and makes corrections.

Ball Screws

Convert rotary motor motion to precise linear table movement. Ball screws provide low friction and high accuracy.

Spindle

Often has more sophisticated controls than manual machines, including variable speed and precise positioning for tool changes.

Tool Changer

Automatic tool changers (ATCs) allow multiple operations without operator intervention. The machine selects tools from a magazine or carousel as programmed.

G-Code Programming

CNC machines understand G-code, a standardized programming language:

text

G00 X25 Y30 (Rapid move to position)

G01 Z-5 F100 (Feed to depth at 100 mm/min)

G01 X50 F200 (Cut to X=50 at 200 mm/min)

G00 Z5 (Rapid retract)

Common G-codes include:

- G00: Rapid positioning

- G01: Linear interpolation (cutting move)

- G02: Circular interpolation clockwise

- G03: Circular interpolation counterclockwise

- G28: Return to reference point

Common M-codes (miscellaneous functions) include:

- M03: Spindle on clockwise

- M05: Spindle stop

- M08: Coolant on

- M09: Coolant off

- M30: Program end

How Students Use CNC in Manufacturing Technology 2

Students typically:

- Learn G-code fundamentals through exercises

- Write simple programs by hand

- Simulate programs on computers

- Run programs on training machines

- Progress to producing actual parts

Modern Manufacturing Technology 2 courses often use educational CNC machines that are safer and more affordable than production equipment while teaching the same concepts.

Advantages of CNC

CNC offers significant benefits:

- Consistent accuracy regardless of operator skill

- Ability to run complex programs

- Reduced setup time for repeat jobs

- Better surface finish from constant cutting conditions

- Capability for unmanned operation

- Easy modification of programs for design changes

Basics Of CAD CAM For Process Planning

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) work together to streamline manufacturing.

What Is CAD?

CAD software creates digital models of parts and assemblies. Instead of drawing on paper, engineers create accurate 3D models that contain all geometric information.

CAD models provide:

- Precise dimensions

- Complex surface definitions

- Assembly relationships

- Material specifications

- Drawing generation

Common CAD software includes:

- SolidWorks

- Autodesk Inventor

- Fusion 360

- CATIA

- Siemens NX

What Is CAM?

CAM software converts CAD models into manufacturing instructions. It generates the tool paths and G-code programs that CNC machines execute.

CAM programming involves:

- Importing the CAD model

- Defining the stock material

- Setting up the coordinate system

- Selecting operations (facing, pocketing, drilling, etc.)

- Choosing tools and parameters

- Generating tool paths

- Simulating to verify

- Post-processing to create machine-specific code

The CAD/CAM Workflow

The typical workflow connects design and manufacturing:

- Design: Create 3D CAD model

- Analysis: Check for manufacturing feasibility

- Planning: Determine operations and sequence

- Programming: Generate CAM tool paths

- Verification: Simulate machining virtually

- Manufacturing: Run program on CNC machine

- Inspection: Verify part meets specifications

Process Planning Basics

Process planning determines how to make a part:

- What operations are needed?

- In what sequence?

- Which machines will be used?

- What tools are required?

- What fixtures are needed?

- What are the cutting parameters?

Manufacturing Technology 2 teaches basic process planning skills. Students learn to analyze part drawings and develop logical manufacturing sequences.

Benefits of CAD/CAM Integration

Integrated CAD/CAM systems offer:

- Faster programming from imported geometry

- Automatic updates when designs change

- Reduced errors from manual data entry

- Virtual verification before cutting metal

- Documentation of manufacturing processes

Automation, Robotics, And Industry 4.0 Overview

Manufacturing continues evolving toward greater automation and connectivity. Manufacturing Technology 2 introduces these trends.

Industrial Robots

Robots perform repetitive tasks with consistency and precision:

Types of Industrial Robots

- Articulated robots: Multiple rotating joints, like a human arm

- SCARA robots: Selective compliance arm, for assembly

- Cartesian robots: Linear axes for simple pick-and-place

- Delta robots: Parallel linkages for high-speed picking

- Collaborative robots (cobots): Work safely alongside humans

Robot Applications in Manufacturing

- Material handling and loading

- Welding and cutting

- Painting and coating

- Assembly operations

- Inspection and testing

Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) combine:

- Multiple CNC machines

- Automated material handling

- Central computer control

- Ability to produce various parts

FMS offers high productivity with flexibility for product variety.

Industry 4.0 Concepts

Industry 4.0, also called the fourth industrial revolution, transforms manufacturing through:

Internet of Things (IoT)

Machines connected to networks share data. Sensors monitor conditions and report to central systems.

Big Data Analytics

Large amounts of production data are analyzed to find patterns, predict problems, and optimize processes.

Digital Twins

Virtual copies of physical systems allow simulation and optimization without affecting actual production.

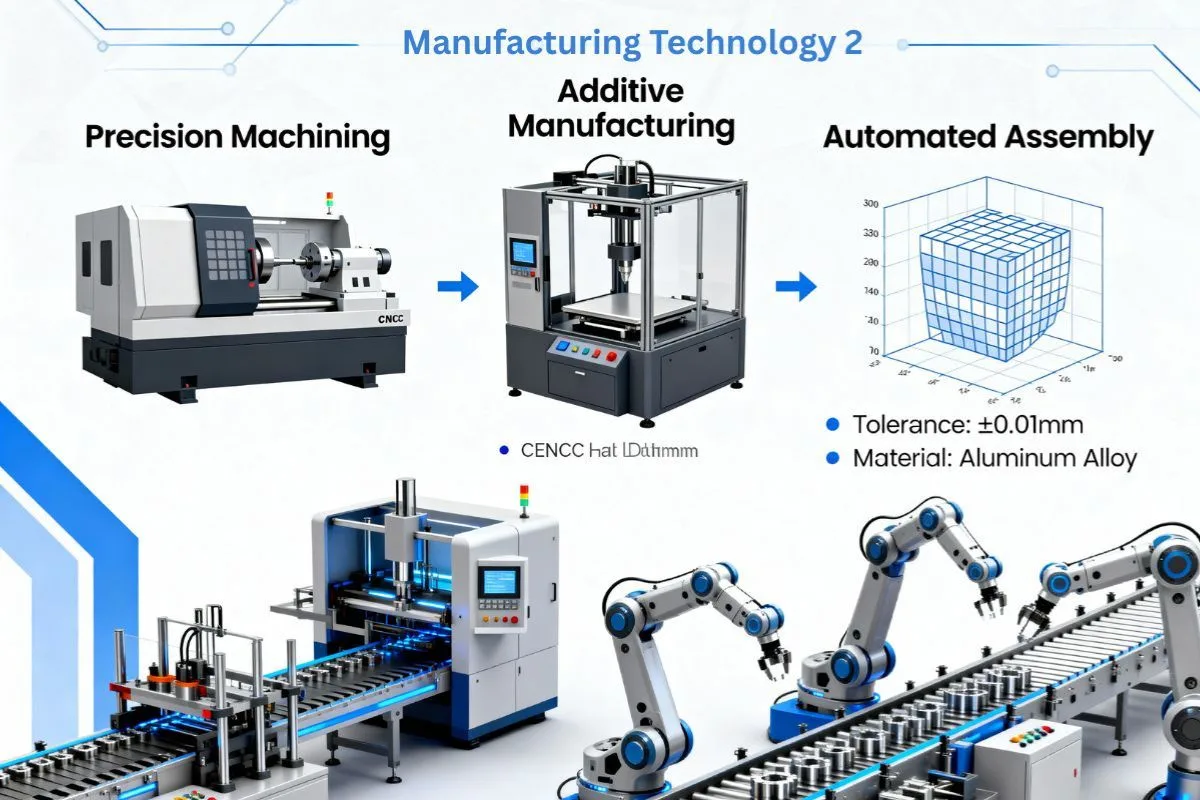

Additive Manufacturing

3D printing creates parts by adding material layer by layer. While Manufacturing Technology 2 focuses mainly on traditional processes, additive manufacturing is increasingly included.

Cloud Computing

Manufacturing data and software are hosted on remote servers, accessible from anywhere.

How This Affects Manufacturing Technology 2 Students

Students today must prepare for a manufacturing environment that looks different from a decade ago:

- Basic programming and computer skills matter more

- Understanding data and networks becomes important

- Continuous learning is essential as technology evolves

- Combining traditional knowledge with digital skills creates value

Manufacturing Technology 2 provides foundational knowledge that remains relevant while introducing concepts that lead to advanced topics.

Quality Control And Productivity In Manufacturing Technology 2

Making parts means nothing if they don’t meet requirements. Manufacturing Technology 2 teaches quality control and productivity concepts essential for manufacturing success.

Measurements, Fits, And Tolerances

No manufacturing process produces perfect dimensions. Understanding and managing dimensional variation is crucial.

Why Tolerances Exist

Consider a shaft that must fit into a hole. If both are exactly 25.000 mm, they won’t fit together there’s no clearance. If the hole is much larger than the shaft, the fit will be too loose.

Tolerances define acceptable variation:

- Nominal size: The target dimension

- Upper limit: Maximum acceptable size

- Lower limit: Minimum acceptable size

- Tolerance: The difference between limits

Expressing Tolerances

Tolerances appear in several formats:

Bilateral tolerances: Allow variation in both directions

- 25.00 ± 0.05 means acceptable range is 24.95 to 25.05

Unilateral tolerances: Allow variation in one direction only

- 25.00 +0.05/-0.00 means acceptable range is 25.00 to 25.05

Limit dimensions: Specify the limits directly

- 25.00/25.05 means any value in that range is acceptable

Fits Between Mating Parts

When parts assemble together, the fit determines how they relate:

Clearance Fit

The shaft is always smaller than the hole. Parts slide together easily. Used where parts must move relative to each other.

Interference Fit

The shaft is always larger than the hole. Parts must be forced or heated/cooled to assemble. Creates a strong, permanent joint.

Transition Fit

Depending on actual sizes within tolerances, there may be clearance or interference. Used where some location control is needed without guaranteed tightness.

Geometric Tolerances

Size tolerances don’t control everything. A shaft could be the correct diameter but not straight. Geometric tolerances control:

- Straightness: How much a line deviates from perfectly straight

- Flatness: How much a surface deviates from a perfect plane

- Roundness: How much a circle deviates from perfect

- Perpendicularity: How much an angle deviates from 90 degrees

- Parallelism: How much surfaces deviate from perfectly parallel

- Concentricity: How much axes deviate from coincident

Manufacturing Technology 2 introduces these concepts so students understand complete part specifications.

Surface Finish

Surface quality affects function:

- Rough surfaces cause wear and friction

- Smooth surfaces seal better

- Very smooth surfaces are expensive to produce

Surface finish is measured in Ra (average roughness) or similar measures. Manufacturing Technology 2 teaches how different processes produce different surface finishes.

Inspection Tools And Gauges

Measuring manufactured parts requires appropriate instruments. Manufacturing Technology 2 covers common inspection tools.

Calipers

Calipers measure outside dimensions, inside dimensions, and depths:

Vernier Calipers

Combine a main scale with a vernier scale for readings to 0.02 mm or 0.001 inch. Reading requires aligning scale lines and adding values.

Dial Calipers

Replace the vernier scale with a dial indicator. Easier to read quickly.

Digital Calipers

Display readings numerically. Most convenient for reading and can interface with computers.

Calipers are versatile for general measurement but have limited precision compared to micrometers.

Micrometers

Micrometers provide higher precision, typically 0.01 mm or 0.001 mm:

Outside Micrometers

Measure external dimensions like shaft diameters. The spindle advances when the thimble turns.

Inside Micrometers

Measure internal dimensions like hole diameters.

Depth Micrometers

Measure depths of holes and steps.

Micrometer technique matters, proper feel and reading skills come with practice.

Dial Indicators

Dial indicators measure small variations:

- Detecting runout (wobble)

- Checking flatness

- Comparing to reference standards

- Setting up workpieces

They don’t measure absolute size but rather deviation from a reference.

Gauge Blocks

Gauge blocks are precision standards for calibration and measurement setup. They can be wrung together to create specific dimensions.

Go/No-Go Gauges

For rapid inspection, go/no-go gauges check if dimensions fall within tolerance:

- The “go” end should fit if the part is acceptable

- The “no-go” end should not fit if the part is acceptable

These gauges don’t measure actual size but verify parts are within limits.

Other Inspection Tools

Manufacturing Technology 2 may also cover:

- Height gauges for vertical measurements

- Bore gauges for internal diameters

- Thread gauges for thread inspection

- Surface roughness testers

- Coordinate Measuring Machines (CMMs)

Simple Steps To Improve Productivity And Reduce Waste

Manufacturing must be both good quality and efficient. Manufacturing Technology 2 introduces productivity improvement concepts.

Understanding Productivity

Productivity compares output to input:

Productivity = Output / Input

Improving productivity means getting more output from the same input or the same output from less input.

Lean Manufacturing Basics

Lean manufacturing focuses on eliminating waste. The seven wastes (muda) are:

- Overproduction: Making more than needed

- Waiting: Idle time waiting for materials, information, or machines

- Transportation: Unnecessary movement of materials

- Processing: Extra operations that don’t add value

- Inventory: Excess materials sitting idle

- Motion: Unnecessary movement by people

- Defects: Products requiring rework or scrap

5S Workplace Organization

The 5S system organizes work areas:

- Sort: Remove unnecessary items

- Set in Order: Organize remaining items logically

- Shine: Clean the workspace

- Standardize: Create consistent procedures

- Sustain: Maintain the improvements

A 5S workplace improves efficiency and safety while reducing errors.

Reducing Cycle Time

Cycle time is how long it takes to complete one unit. Reducing cycle time increases output:

- Minimize setup time

- Optimize cutting parameters

- Reduce non-cutting movements

- Improve material handling

- Eliminate unnecessary operations

Setup Time Reduction

Frequent product changes mean frequent setups. Reducing setup time increases available production time:

- Prepare tools and materials before stopping the machine

- Use quick-change tooling

- Standardize setups where possible

- Practice and refine procedures

Quality Improvement

Poor quality wastes resources:

- Scrap parts waste material and machining time

- Rework takes additional time

- Customer returns cost money and reputation

Doing things right the first time is always more efficient than fixing problems later.

Connecting to Manufacturing Technology 2

These concepts apply directly to Manufacturing Technology 2 projects:

- Plan operations carefully before starting

- Prepare tools and measure stock before machining

- Use appropriate cutting conditions

- Check measurements during the process

- Clean and organize your work area

Students who develop good habits in Manufacturing Technology 2 laboratories carry those habits into their careers.

Real-World Examples That Bring Manufacturing Technology 2 To Life

Abstract concepts become clearer with concrete examples. This section walks through manufacturing scenarios that connect Manufacturing Technology 2 content to real production.

Example 1 From Raw Bar To Finished Part

Consider manufacturing a simple stepped shaft like those used in gearboxes. This example shows how Manufacturing Technology 2 knowledge applies.

The Part

The shaft has:

- Overall length: 120 mm

- Large diameter section: 25 mm diameter, 70 mm long

- Small diameter section: 18 mm diameter, 50 mm long

- Surface finish: Ra 1.6 μm on both diameters

- Tolerances: ±0.05 mm on diameters

Starting Material

We start with 28 mm diameter round bar stock. The extra 3 mm provides material for cleanup cuts and allows for any straightness issues in the bar.

Process Planning

The manufacturing sequence:

- Cut stock to approximately 125 mm length

- Face both ends to establish length reference

- Rough turn large diameter leaving 0.5 mm for finishing

- Rough turn small diameter leaving 0.5 mm for finishing

- Finish turn large diameter to final dimension

- Finish turn small diameter to final dimension

- Chamfer edges

- Final inspection

Detailed Operations

Cutting Stock

Using a power hacksaw or bandsaw, cut the bar approximately 5 mm longer than the final length. This provides material for facing operations.

Setup on Lathe

Mount the bar in a three-jaw chuck. Face the exposed end to create a flat reference surface. Reverse the part and face the other end to final length.

Rough Turning

For the 25 mm section:

- Calculate spindle speed based on cutting velocity (perhaps 100 m/min for medium carbon steel with carbide tooling)

- N = (100 × 1000) / (π × 28) ≈ 1137 RPM

- Use a moderate feed rate (0.2 mm/rev) and depth of cut (1.5 mm)

- Take passes until diameter reaches approximately 25.5 mm

For the 18 mm section:

- Recalculate spindle speed for smaller diameter

- Turn down to approximately 18.5 mm

Finish Turning

- Reduce depth of cut to 0.25 mm

- Reduce feed rate to 0.1 mm/rev for better surface finish

- Take final cut to achieve 25.00 mm and 18.00 mm

Checking Dimensions

Use micrometer to verify:

- Large diameter: 24.95 to 25.05 mm acceptable

- Small diameter: 17.95 to 18.05 mm acceptable

- Length measurements

Surface Finish Verification

Surface roughness tester confirms Ra meets 1.6 μm requirement.

Manufacturing Technology 2 Connections

This example applies:

- Cutting speed and spindle speed calculations

- Understanding of roughing and finishing operations

- Knowledge of surface finish factors

- Measurement skills with micrometers

- Tolerance interpretation

Example 2 Casting, Machining, And Finishing Flow

Some parts combine multiple processes. Consider a pump housing that requires casting followed by machining.

The Part

The pump housing is a complex shape with:

- External flanges for mounting

- Internal cavity for the impeller

- Machined mounting surfaces

- Threaded holes for assembly

Why Casting?

The complex internal shape would be very difficult to machine from solid material. Casting creates the basic shape efficiently, then machining adds precision features.

Pattern Making

A pattern slightly larger than the final part accounts for:

- Shrinkage during solidification (typically 1-2% for aluminum)

- Machining allowance on surfaces that need precision

- Draft angles for pattern removal

Mold Making

Sand casting uses:

- Cope and drag mold halves

- Cores for internal cavities

- Gating system for metal flow

- Risers for shrinkage feeding

The pattern creates the cavity when removed from packed sand.

Casting

Molten aluminum is poured at approximately 700°C. It fills the mold cavity, and the risers remain open to feed metal as the casting shrinks during solidification.

Cleaning

After cooling:

- Break away sand mold

- Remove gates and risers

- Clean surfaces by shot blasting

- Inspect for casting defects

Machining Operations

The casting now receives precision features:

Face Milling

Mount the casting and face mill the mounting surfaces to achieve flatness and proper thickness.

Boring

Bore the internal cylindrical surfaces to precise dimensions for bearings or seals.

Drilling

Drill mounting holes in the flanges.

Tapping

Tap threads in appropriate holes.

Finishing

The completed housing may receive:

- Deburring to remove sharp edges

- Surface treatment for corrosion protection

- Pressure testing to verify no porosity

- Dimensional inspection

Manufacturing Technology 2 Connections

This example demonstrates:

- How casting creates basic shapes

- Why machining is needed after casting

- Process sequence logic

- Multiple machine operations

- Quality verification

Example 3 CNC Cell In A Modern Factory

Modern production often uses CNC machining cells. Consider how such a cell operates.

Cell Configuration

A typical CNC turning cell might include:

- CNC lathe with live tooling

- Bar feeder for automatic stock supply

- Chip conveyor for waste removal

- Coolant system

- Robot for part loading/unloading

- Inspection station

Automatic Operation

The cell operates with minimal human intervention:

- Bar feeder pushes stock into lathe chuck

- CNC program executes all turning operations

- Live tooling performs milling, drilling, and threading

- Completed part is parted off

- Robot transfers part to inspection station

- Good parts proceed to shipping; rejected parts are segregated

- Cycle repeats

The Program

The CNC program contains all instructions:

text

(SETUP: BAR STOCK 25MM DIA)

G28 U0 W0 (RETURN TO HOME)

T0100 (SELECT TOOL 1)

G50 S3000 (MAX SPINDLE SPEED)

G96 S150 M03 (CONSTANT SURFACE SPEED)

G00 X26 Z2 (RAPID TO START)

G01 Z0 F0.1 (FACE CUT)

G00 X0 (TO CENTER)

…

(PROGRAM CONTINUES WITH ALL OPERATIONS)

Advantages of This Configuration

- High production rate with minimal labor

- Consistent quality from programmed operations

- Lights-out capability for unmanned shifts

- Flexibility to change programs for different parts

Human Roles

Humans still play important roles:

- Programming and optimizing CNC code

- Setting up the cell for new products

- Maintaining machines and tools

- Responding to problems

- Continuous improvement activities

Manufacturing Technology 2 Connections

This example shows how Manufacturing Technology 2 knowledge scales to production:

- CNC programming fundamentals apply directly

- Understanding of turning operations informs program development

- Tool selection knowledge remains essential

- Quality concepts determine inspection requirements

- Productivity ideas guide cell design

Pros And Cons Of Modern Manufacturing Technologies

Manufacturing Technology 2 prepares students to make informed decisions. Understanding advantages and disadvantages helps with process selection.

Traditional Vs CNC And Automated Processes

Both traditional and modern methods have their place. Comparing them helps clarify when to use each.

Traditional (Manual) Machining

How It Works

Skilled machinists control every aspect of the operation. They read drawings, set up machines, and manipulate controls by hand and eye.

Advantages

- Low equipment cost compared to CNC

- Flexibility for one-off parts

- Quick setup for simple operations

- Skilled machinist can adapt instantly to issues

- No programming required

- Good for teaching fundamental concepts

Disadvantages

- Dependent on operator skill

- Inconsistency between operators or even between parts

- Slower production rates

- Fatigue affects quality over long runs

- Limited complexity achievable economically

- Higher labor cost per part for production quantities

CNC Machining

How It Works

Programmed instructions control machine movements. Once programmed and set up, the machine repeats operations identically.

Advantages

- Consistent quality regardless of operator skill

- Complex shapes machined easily

- High production rates

- Reduced labor per part

- Programs stored and reused

- Integration with CAD/CAM systems

- Automatic tool changes

Disadvantages

- High equipment cost

- Requires programming skills

- Setup time significant for single parts

- Programming errors can cause crashes

- Maintenance requires specialized skills

- Power consumption higher

When to Choose Each

Choose Manual Machining When:

- Making one or very few parts

- Part is simple

- Setup time exceeds machining time

- Budget is limited

- Training machinists in fundamentals

Choose CNC Machining When:

- Production quantities are higher

- Part geometry is complex

- Consistency is critical

- Tight tolerances required

- Production will repeat in the future

Pros And Cons Table For New Manufacturing Technology

This table summarizes considerations for various manufacturing technologies covered in Manufacturing Technology 2:

| Technology | Pros | Cons | Best For |

| Manual Machining | Low cost, flexible, quick setup for simple parts | Skill dependent, inconsistent, slower | One-offs, simple parts, learning |

| CNC Machining | Accurate, consistent, efficient for production | Expensive, requires programming | Repeat production, complex parts |

| Sand Casting | Low tooling cost, any size, any metal | Rough surface, limited accuracy | Complex shapes, low volumes |

| Die Casting | Excellent finish, fast production | High die cost, limited to certain metals | High volume production |

| Manual Welding | Versatile, low equipment cost | Skill dependent, slower | Repair, construction, custom work |

| Robot Welding | Fast, consistent, good for production | High cost, limited flexibility | Repeat welding operations |

| Conventional Forming | Lower equipment cost | Slower, labor intensive | Low volumes, large parts |

| CNC Forming | Precise, consistent | Expensive equipment | Production forming, precision |

| 3D Printing | Complex shapes, no tooling | Slow, limited materials, surface finish | Prototypes, custom parts |

How To Choose The Right Process In Manufacturing Technology 2

Students face process selection decisions in assignments and eventually in careers. Here’s a systematic approach.

Step 1: Analyze the Part

Examine the part to understand requirements:

- What is the material?

- What are the dimensions and tolerances?

- What surface finishes are required?

- What is the quantity needed?

- What is the budget?

- When is delivery required?

Step 2: Identify Possible Processes

List processes that could create the part:

- Can it be machined from stock?

- Should it be cast then machined?

- Can it be formed?

- Does it need welding for assembly?

Multiple valid approaches often exist.

Step 3: Evaluate Each Option

For each possible process, consider:

- Can it achieve required tolerances?

- Can it produce the required surface finish?

- What equipment is available?

- What is the cost per part?

- What is the lead time?

- What skills are required?

Step 4: Consider Secondary Operations

Primary processes rarely complete parts alone:

- Heat treatment for properties

- Surface finishing for appearance/protection

- Inspection for quality verification

- Deburring for safety and function

Include these in your evaluation.

Step 5: Compare and Decide

Create a comparison matrix:

| Criterion | Weight | Option A | Option B | Option C |

| Cost | 30% | Score | Score | Score |

| Quality | 25% | Score | Score | Score |

| Delivery | 20% | Score | Score | Score |

| Capability | 25% | Score | Score | Score |

| Total | 100% | Sum | Sum | Sum |

The highest-scoring option usually makes the best choice, but uses judgment when scores are close.

Step 6: Document Your Decision

Record why you chose the process. This helps with future similar decisions and demonstrates your reasoning.

Example Decision

Consider making 500 aluminum pulleys:

- Material: Aluminum alloy

- Diameter: 100 mm

- Tolerance: ±0.1 mm

- Finish: Ra 3.2 μm

Options:

- Machine from bar stock

- Die cast then machine

- Sand cast then machine

Analysis:

For 500 pieces, die casting die cost may not be justified. Sand casting followed by machining could work, but 500 pieces makes even sand casting costly per piece. Machining from bar stock on CNC lathe is likely most economical.

Decision: CNC turning from bar stock.

This systematic approach helps Manufacturing Technology 2 students develop process selection skills that serve them throughout their careers.

Studying, Exams, And Careers Linked To Manufacturing Technology 2

Manufacturing Technology 2 isn’t just about learning, it’s about preparing for exams and careers. This section provides practical guidance.

How To Study Manufacturing Technology 2 Effectively

Success in Manufacturing Technology 2 requires effective study strategies.

Understand, Don’t Just Memorize

Manufacturing Technology 2 involves principles that interconnect. Understanding why things work helps more than memorizing facts:

- Why does cutting speed affect tool life?

- Why does casting require risers?

- Why do tolerances matter for assembly?

When you understand principles, you can answer questions you’ve never seen before.

Connect Theory to Practice

Manufacturing Technology 2 combines classroom learning with laboratory work. Connect them:

- Before lab, review relevant theory

- During lab, observe what theory predicts

- After lab, reflect on what you learned

The connection strengthens understanding in both directions.

Use Visual Learning

Manufacturing processes are inherently visual. Supplement text with:

- Videos of machining operations

- Animations of CNC tool paths

- Photographs of casting processes

- Diagrams of machine components

YouTube and educational websites offer extensive visual resources.

Practice Calculations

Manufacturing Technology 2 includes calculations:

- Cutting speed and spindle speed

- Feed rates and material removal rates

- Tool life predictions

- Process time estimates

Practice these until they become automatic. Work problems beyond what’s assigned.

Create Summary Notes

Condensing course material helps learning:

- One page per major topic

- Key formulas and relationships

- Process comparisons

- Important terminology

These summaries become valuable revision tools.

Study Groups

Working with classmates helps:

- Explain concepts to each other

- Practice problem solving together

- Quiz each other before exams

- Share notes and resources

Teaching someone else is one of the best ways to learn.

Relate to Real Products

Look at everyday objects with manufacturing eyes:

- How was this phone case made?

- What processes created this bicycle frame?

- How were threads cut on this bolt?

This habit reinforces learning and builds intuition.

Common Exam Question Types In Manufacturing Technology 2

Understanding question types helps exam preparation.

Definition Questions

These ask you to explain terms or concepts:

“Define cutting speed and explain how it differs from spindle speed.”

For these questions:

- State a clear definition

- Add brief explanation or context

- Use an example if appropriate

Comparison Questions

These ask you to contrast processes or methods:

“Compare sand casting and die casting for producing aluminum parts.”

For these questions:

- Structure your answer (table format often works)

- Address multiple comparison criteria

- Conclude with when each is preferred

Calculation Questions

These require numerical work:

“Calculate the spindle speed required to turn a 50 mm diameter bar at a cutting speed of 120 m/min.”

For these questions:

- Write the formula

- Substitute values clearly

- Show calculation steps

- State answer with units

Process Selection Questions

These present scenarios requiring judgment:

“You need to manufacture 100 steel brackets. Describe the manufacturing process you would use and justify your choice.”

For these questions:

- Analyze requirements

- Consider alternatives

- Explain your reasoning

- Address practical considerations

Diagram Questions

These ask you to draw and label:

“Sketch a lathe and label major components.”

For these questions:

- Draw clearly (rulers help)

- Label accurately

- Add brief annotations if relevant

Short Answer Questions

These require concise responses:

“List five factors that affect surface finish in turning.”

For these questions:

- Answer directly

- Use complete thoughts

- Prioritize most important points

Essay Questions

These require extended responses:

“Discuss how Industry 4.0 technologies are transforming manufacturing processes.”

For these questions:

- Plan before writing

- Organize with introduction, body, conclusion

- Use specific examples

- Demonstrate breadth and depth of knowledge

Jobs And Higher Study Paths After Manufacturing Technology 2

Manufacturing Technology 2 opens doors to various opportunities.

Entry-Level Manufacturing Roles

CNC Operator

Operates CNC machines to produce parts. Entry requirements often include Manufacturing Technology 2 or equivalent training. Progression leads to CNC programmer or setup technician roles.

Typical salary range (varies by location):

- USA: $35,000 – $50,000

- UK: £22,000 – £32,000

- Australia: AUD 50,000 – 70,000

Manufacturing Technician

Supports production operations through setup, troubleshooting, and quality checks. Manufacturing Technology 2 provides a relevant background.

Quality Inspector

Measures and inspects parts using skills from Manufacturing Technology 2. Career progression leads to quality engineering or management.

Technical Roles Requiring Further Education

Manufacturing Engineer

Designs and improves manufacturing processes. Typically requires bachelor’s degree including Manufacturing Technology 2 and advanced courses.

Process Engineer

Develops and optimizes specific processes. Combines Manufacturing Technology 2 knowledge with specialization.

Production Supervisor

Manages manufacturing teams. Combines technical knowledge with leadership skills.

Higher Study Options

Advanced Manufacturing Courses

- Computer Integrated Manufacturing

- Advanced CNC Programming

- Additive Manufacturing

- Composites Manufacturing

Degree Pathways

- Bachelor’s in Manufacturing Engineering

- Bachelor’s in Mechanical Engineering with manufacturing focus

- Bachelor’s in Industrial Engineering

Professional Certifications

- Certified Manufacturing Technologist (CMfgT)

- Certified Manufacturing Engineer (CMfgE)

- CNC programming certifications from vendors

- Quality certifications (ASQ)

Industry Sectors

Manufacturing Technology 2 knowledge applies across industries:

- Automotive manufacturing

- Aerospace production

- Medical device manufacturing

- Consumer electronics

- Energy equipment

- General industrial machinery

Geographic Considerations

Manufacturing employment varies by region:

- USA: Strong in automotive (Michigan, Ohio), aerospace (Washington, California), medical devices (Massachusetts, Minnesota)

- UK: Aerospace (Bristol), automotive (Midlands), precision engineering (throughout)

- Germany: Automotive (Bavaria, Baden-Württemberg), machinery (throughout)

- Australia: Mining equipment, medical devices, defense

- Canada: Automotive (Ontario), aerospace (Quebec)

Summary And Next Steps

We’ve covered extensive ground in this Manufacturing Technology 2 guide. Let’s summarize key points and suggest paths forward.

Key Takeaways From Manufacturing Technology 2

Core Processes Matter

Understanding machining, casting, forming, and joining gives you vocabulary and concepts that apply across manufacturing. Whether you operate machines or manage factories, this knowledge remains relevant.

Machines Are Tools

Lathes, mills, and drills are tools for achieving results. Understanding their capabilities and limitations helps you select appropriate equipment and set realistic expectations.

Quality Is Non-Negotiable

Tolerances, measurements, and inspection ensure parts function properly. Manufacturing Technology 2 teaches you to think about quality from the start of every project.

Modern Technology Enhances Fundamentals

CNC, CAD/CAM, and automation build on traditional knowledge rather than replacing it. Understanding manual processes helps you appreciate and effectively use computerized versions.

Safety Protects Everyone

Workshop safety rules exist because the hazards are real. Developing safe habits in Manufacturing Technology 2 labs protects you throughout your career.

Process Selection Requires Judgment

No single process is best for everything. Manufacturing Technology 2 teaches you to analyze requirements and make informed decisions.

Continuous Learning Is Essential

Manufacturing technology evolves constantly. The foundation from Manufacturing Technology 2 prepares you to learn new methods as they emerge.

Where To Learn More About Manufacturing Technology 2

Textbooks

Several textbooks support Manufacturing Technology 2 learning:

- “Manufacturing Engineering and Technology” by Kalpakjian and Schmid

- “Fundamentals of Modern Manufacturing” by Groover

- “Manufacturing Processes for Engineering Materials” by Kalpakjian and Schmid

- “Workshop Technology” by Chapman (for UK-focused content)

Online Resources

- MIT OpenCourseWare offers manufacturing courses

- YouTube channels like Engineering Guy explain processes visually

- Practical Machinist forums provide real-world perspectives

- Autodesk and SolidWorks offer CAD/CAM tutorials

Professional Organizations

- Society of Manufacturing Engineers (SME)

- American Society of Mechanical Engineers (ASME)

- Institution of Mechanical Engineers (IMechE) in UK

- Manufacturing Technologies Association

Standards

Understanding standards helps in professional settings:

- ISO standards for quality and tolerances

- ANSI standards for US practices

- DIN standards for German engineering

- AS standards for Australia

Industry Publications

- Modern Machine Shop

- American Machinist

- Manufacturing Engineering Magazine

Hands-On Practice

Nothing replaces hands-on experience:

- Use laboratory time fully

- Seek internships or co-op positions

- Consider makerspaces for additional practice

- Pursue projects outside of class

Manufacturing Technology 2 provides a foundation for understanding how things are made. The knowledge serves whether you pursue engineering degrees, enter manufacturing directly, or simply want to appreciate the products around you. With this foundation, you’re ready to explore deeper topics, tackle real-world challenges, and contribute to manufacturing’s future.